Introduction

In an era where environmental degradation and climate change are the global concerns, the need for sustainable solutions in all sectors is more pressing than ever. Green chemistry provides sustainable solutions that protect the environment, streamline production processes, lower costs, and drive innovation across global industries.

Did you know that traditional chemical manufacturing can produce over 2,000 pounds of waste for every 100 pounds of usable product? Green chemistry offers a revolutionary approach to chemical manufacturing that could change these statistics forever. This innovative field combines cutting-edge science with environmental responsibility, creating sustainable solutions that reduce waste, save energy, and protect our planet’s resources.

From pharmaceutical manufacturing to agricultural solutions and clean energy production, green chemistry transforms how industries operate. This comprehensive guide explores the fundamental principles of green chemistry, breakthrough technologies, industrial applications, and economic benefits. We’ll also examine future trends and challenges shaping this rapidly evolving field.

What is Green Chemistry?

Green chemistry, often referred to as sustainable chemistry, is the design of chemical products and processes that minimize or eliminate the use and generation of hazardous substances. It goes beyond pollution control instead of cleaning up harmful by-products, it prevents them from forming in the first place.

This scientific philosophy integrates sustainability into the very foundation of chemical design. It aims to achieve a balance between innovation, performance, and environmental protection, ensuring that human progress does not come at the expense of ecological health.

The concept was formulated by Paul Anastas & John Warner in their book Green Chemistry. Theory and Practice (1998), where they introduced the 12 principles of green chemistry. These principles are designed to guide scientists, engineers, and industries in making greener choices at every stage of the chemical process, from the design of products to their disposal.

The 12 Principles of Green Chemistry

-

Prevention of Waste

Avoid creating waste rather than treating or cleaning it up afterward.

-

Atom Economy

Design reactions to incorporate all materials used in the process into the final product.

-

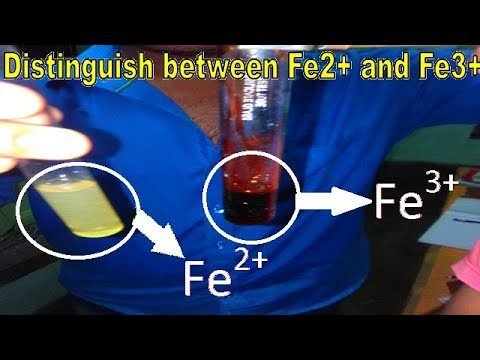

Less Hazardous Chemical Synthesis

Choose synthetic methods that reduce toxicity to humans and the environment.

-

Designing Safer Chemicals

Develop products that achieve their function while being less toxic.

-

Safer Solvents and Reaction Conditions

Use safer substances, or eliminate the need for solvents entirely.

-

Energy Efficiency

Run processes at room temperature and pressure whenever possible.

-

Renewable Feedstocks

Use raw materials from renewable sources instead of fossil fuels.

-

Reduce Derivatives

Avoid unnecessary modifications like blocking or protecting groups.

-

Catalysis

Use catalysts to increase reaction efficiency and minimize waste.

-

Design for Degradation

Ensure products break down into harmless substances after use.

-

Real-Time Analysis

Monitor reactions in real-time to prevent pollution.

-

Accident Prevention

Choose materials and forms that minimize the risk of accidents like explosions or spills.

Why Green Chemistry is Important?

The importance of green chemistry cannot be overstated. Here’s why:

Environmental Impact Evaluation

Green chemistry employs innovative strategies for assessing ecological effects. The life cycle assessment (LCA) approach also known as life cycle thinking (LCT) analyzes products from raw material acquisition to end-of-life disposal, ensuring a comprehensive evaluation of environmental sustainability. This methodology has proven especially valuable in the pharmaceutical sector, where conventional production processes once generated over 100 kilograms of waste for every kilogram of active pharmaceutical compound manufactured.

Sustainable Development Objectives

Green chemistry plays a pivotal role in advancing global sustainability milestones. The American Chemical Society (ACS) has outlined seven key Sustainable Development Goals (SDGs) where chemistry provides essential contributions:

- Responsible consumption and production

- Clean water and sanitation

- Affordable and clean energy

- Climate action

- Industry, innovation, and infrastructure

- Sustainable cities and communities

- Decent work and economic growth

The chemical manufacturing sector is actively supporting these objectives by implementing circular economy principles and developing innovative business frameworks that move beyond the concept of single-use material. For instance, chemical advancements are optimizing industrial processes, improving water management initiatives, and enhancing energy utilization efficiency across multiple sectors.

The discipline continues to progress, with emerging innovations emphasizing real-time monitoring for pollution mitigation and inherently safer chemical design to prevent industrial accidents. This preventive and design-oriented approach marks a fundamental shift from conventional end-of-pipe treatment systems, establishing green chemistry as a leader in sustainable industrial transformation.

Emerging Innovations in Sustainable Chemical Technologies

Remarkable advancements in eco-conscious chemical technologies are transforming industrial operations, making them significantly more sustainable, resource-efficient, and environmentally responsible than ever before. These trailblazing developments are redefining standards in modern chemical production and driving the next era of sustainable manufacturing excellence.

Catalysis and Biocatalysis

The field of biocatalysis has undergone extraordinary expansion, driven by recent breakthroughs in genetic engineering technologies. These advancements have facilitated the accelerated creation of novel enzyme variants exhibiting superior stability and enhanced functional performance. The benefits of enzyme-based processes are truly remarkable:

- Exceptional reaction selectivity

- Capability to operate efficiently at ambient temperature

- Functionality in aqueous environments

- Increased durability through enzyme immobilization

- Greater resistance to structural denaturation

Recent progress has demonstrated that enzymes can now perform effectively within organic solvents, unveiling entirely new horizons for industrial implementation. Moreover, the emergence of enzyme cascade systems—where multiple enzymes act sequentially—has dramatically transformed the landscape of organic synthesis and bioprocess innovation.

Solvent-free Reactions

One of the most promising advancements in sustainable chemistry is the rise of solvent-free reaction methodologies. These cutting-edge strategies provide exceptional advantages in terms of operational efficiency and ecological sustainability. Conducting reactions in the absence of solvents allows for maximum substrate concentration while dramatically lowering the E-factor.

The three principal categories of solvent-free processes have revolutionized chemical synthesis:

- Reactions utilizing mineral oxide adsorption

- Phase-transfer catalysis techniques

- Neat reactions carried out without any auxiliary substances

These approaches have demonstrated outstanding effectiveness in microwave-assisted organic transformations, achieving remarkably high yields in a fraction of the time required by traditional techniques.

Microvave and Ultrasonic Chemistry

These energy efficient methods speed up reactions and reduce energy consumption, making large scale production cleaner and faster.

Green Nanotechnology

Researchers are developing nanoparticles through sustainable synthesis methods that minimize environmental impact.

Green Synthesis Methods

The discipline has witnessed remarkable progress in sustainable synthesis techniques, especially within biocatalytic systems. These approaches now rival conventional chemical synthesis in both efficiency and versatility. The integration of ionic liquids and deep eutectic solvents has significantly broadened the scope of potential applications.

In pharmaceutical production, such advancements have led to extraordinary improvements. For example, the synthesis of sitagliptin, a vital antidiabetic medication, now utilizes an enzyme-driven process that eliminates metal catalysts while simultaneously enhancing yield, safety, and sustainability.

Looking ahead, the future appears even more promising with the creation of self-regenerating catalysts capable of reforming themselves during reactions, along with solar-activated catalysts that leverage renewable energy sources. These innovations are not only eco-friendly but also economically advantageous, as they minimize waste treatment expenses and maximize material utilization efficiency

Industrial Implementations

The industrial ecosystem is undergoing a profound transformation as green chemistry principles gain momentum across multiple sectors. These pioneering approaches are ushering in cleaner, smarter, and more resource-efficient production systems.

Pharmaceutical Manufacturing

The pharmaceutical domain has achieved notable success in embracing sustainable chemical practices. Between 2004 and 2013, the U.S. pharmaceutical industry reduced its chemical consumption by nearly 50%, primarily through the minimization of organic solvents and the adoption of less hazardous reagents.

A particularly outstanding milestone is Pfizer’s achievement in drug synthesis its sustainability initiatives resulted in a 19% decrease in waste generation and a 56% improvement in productivity compared to previous benchmarks. These advancements not only benefit the environment but also deliver substantial economic returns.

Agricultural Innovations

The agricultural sector is adopting green chemistry with exceptional vigor. Modern farming is being reshaped by sustainable innovations that enhance both yield and ecological stewardship. Key accomplishments include:

- Conversion of agricultural residues into bioenergy and electricity

- Development of biopesticides and biofertilizers

- Utilization of sustainable biomass resources

- Implementation of zero-emission production models

The global impact is immense approximately 140 billion tons of agricultural biomass are generated each year, and green chemistry solutions could help offset nearly 50 billion tons of fossil fuel demand.

Clean Energy Generation

The renewable energy industry demonstrates some of the most inspiring applications of green chemistry. In Australia, researchers are pioneering metal-free carbon-based materials to produce sustainable chemicals and renewable energy with zero emissions. These advancements are pivotal in supporting global decarbonization objectives.

The integration of biomass into energy generation systems has yielded exceptional results. For instance, Brazil exemplifies leadership in this arena, with over 80% of its energy portfolio derived from environmentally responsible technologies. This achievement underscores how green chemistry can revolutionize national energy infrastructures.

The future of industrial applications in green chemistry appears remarkably bright. As innovation and implementation advance, industries are transitioning toward cleaner, more efficient, and inherently sustainable production paradigms.

Cost Efficiency Strategies

Green chemistry has emerged as a transformative force in operational cost management. Organizations adopting sustainable chemical principles are achieving significant financial benefits through:

- Reduced expenditures on waste management and treatment

- Lower raw material costs enabled by renewable feedstocks

- Decreased environmental remediation expenses

- Minimized costs associated with hazard control and safety compliance

In the pharmaceutical industry, while direct synthesis cost reductions may appear limited, the true financial advantage arises from decreased waste remediation and safety management expenses. These advancements hold particular importance for developing nations, where cost-efficient production methods can make essential medicines more affordable and widely accessible.

Economic and Environmental Benefits

The transition to green chemistry is not only environmentally beneficial it makes sound business sense.

Lower Production Costs

Efficient use of materials and energy lowers operational expenses while minimizing waste-disposal costs.

Enhanced Brand Reputation

Companies adopting green practices strengthen their corporate image and meet increasing consumer demand for sustainability.

Regulatory Compliance

As governments introduce stricter environmental standards, green chemistry helps industries stay compliant while maintaining profitability.

Long-Term Environmental Protection

Reduced emissions, waste, and pollution protect biodiversity, air, and water resources — ensuring a livable planet for future generations.

Future Trends and Challenges

While the progress of green chemistry is impressive, continued advancement requires collaboration between scientists, industry leaders, and policymakers.

AI and Machine Learning

Artificial intelligence is being integrated into chemical design to predict greener reaction pathways and optimize energy use.

Global Policy Support

International regulations and incentives are encouraging industries to adopt sustainable practices at scale.

Education and Research

Universities worldwide are incorporating green chemistry into curricula, preparing the next generation of eco-conscious chemists.

Remaining Challenges

The initial cost of implementation and limited awareness in developing regions remain significant barriers to widespread adoption.

Conclusion

Green chemistry stands at the crossroads of science, innovation, and sustainability. By reimagining how chemicals are created and used, it offers a blueprint for a cleaner, safer, and more responsible future.

The transformation is already underway from laboratories to large-scale industries proving that environmental responsibility and economic growth can coexist. As we continue to innovate, one thing becomes clear: the chemistry of tomorrow must be green, efficient, and sustainable.

Frequently Asked Questions (Faqs)

-

What is green chemistry in simple terms?

Green chemistry is the design of chemical products and processes that reduce or eliminate the use and creation of hazardous substances. Its goal is to make chemistry safer, cleaner, and more sustainable.

-

Why is green chemistry important for the environment?

Green chemistry minimizes pollution at its source by preventing harmful substances from being produced. It conserves resources, reduces waste, and helps protect air, water, and soil from chemical contamination.

-

Who developed the principles of green chemistry?

The 12 Principles of Green Chemistry were developed by Dr. Paul Anastas and Dr. John Warner in the late 1990s. Their work established the foundation for sustainable chemical design.

-

How does green chemistry help industries?

Green chemistry helps industries save costs, improve efficiency, and comply with environmental regulations. It also enhances corporate reputation by showing commitment to sustainability.

-

What are some real-world applications of green chemistry?

Green chemistry is used in pharmaceuticals, agriculture, energy, and manufacturing from creating eco-friendly drugs and fertilizers to developing biodegradable plastics and renewable fuels.

-

How is green chemistry different from environmental chemistry?

Environmental chemistry studies how chemicals affect the environment, while green chemistry focuses on preventing pollution through sustainable chemical design and manufacturing.

-

Can green chemistry be cost-effective?

Yes. Although initial investments can be high, green chemistry processes often lower long-term costs through reduced waste, efficient energy use, and fewer regulatory penalties.

-

What are some challenges in implementing green chemistry?

Key challenges include high setup costs, lack of awareness, limited availability of green alternatives, and the need for new training and infrastructure in industries.

Leave a Reply