The word “paper” is derived from the name of a reedy plant, “papyrus,” which grew abundantly along the marshy delta of the River Nile around 3000 B.C. The invention of modern paper is credited to T’sai Lun of China, who, in 105 A.D., was an official attached to the Imperial Court of China. He prepared a sheet of paper using the bark of a mulberry tree that was treated with lime and mixed with bamboo and other fibers to get the paper of desired properties.

Paper

“A sheet of material made up of a network of natural cellulosic fibers that have been deposited from an aqueous suspension is called paper.” The product obtained is a network of intertwining (interlocking) fibers.

Raw Material Required

The main raw material used in the production of pulp and paper in Pakistan is of two types, that is, non-woody and woody raw materials.

Non-Woody Raw Materials

Non-woody raw materials are

- Wheat straw

- Rice straw

- Bagasse

- Bamboo

- Rag

- COtton stalk

- Cotton linter

- Kahi grass

- Grasses

Woody Raw Materials

Woody raw materials are

- Poplar (hardwood)

- Eucalyptus (hardwood)

- Douglas fir (softwood)

Pulping Processes

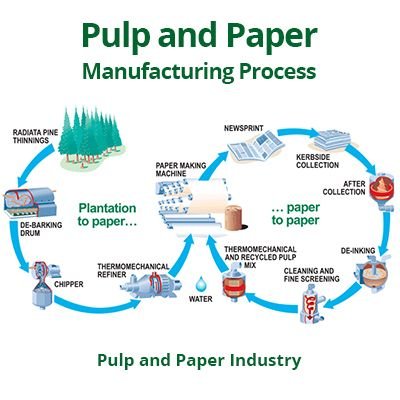

The following are three principal methods of chemical pulping and are used for the production of paper pulps.

- Kraft process (alkaline)

- Sulfite process (acidic)

- Neutral Sulfite Semichemical process (NSSC)

The neutral sulfite semichemical process has come to occupy the dominant position because of the advantages in chemical recovery and pulp strength. In this section, we will discuss only the neutral sulfite semichemical process, which is mostly used in the pulp and paper industry in Pakistan.

Neutral Sulphite Semi-Chemical Process (NSSC)

Process Description

This process utilizes sodium sulfite cooking liquor, which is buffered with sodium carbonate or NaOH to neutralize the organic acid liberated from the raw materials. The non-woody raw materials used in this process are wheat straw, rice straw, bagasse, cotton linter, and rags. Wheat straw may also be used alone or combined with other materials in different proportions. The essential steps in the process are as follows:

- Cutting of the raw materials

- Dry cleaning

- Wet cleaning

- Scree

- Digestion

- Blow tank

- Pulp washing

- Bleaching

- Stock preparation plant

- Paper-making machine

(1) Cutting of Raw Materials

The non-woody raw materials come in the precut state and are processed as such. But in the case of wood-based raw materials, big logs are cut into small chips before further processing.

(2) Dry Cleaning

Wheat straw is collected from the storage and sent for dry cleaning. For this purpose, air is blown into the raw material, which removes unwanted particles.

(3) Wet Cleaning

Dry wheat straw is then subjected to wet cleaning, which not only removes the remaining dust particles but also dissolves the soluble materials in water.

(4) Screening

In most pulp and paper processes, some type of screening operation is required to remove the oversized, troublesome, and unwanted particles.

- The magnetic separator removes iron pieces, which are removed by centrifuging.

- Stones and other oversized pieces are removed by the centri-cleaner. The major types of chest screens are vibratory, gravity, and centrifugal. The material is then sent to the wet silo.

(5) Digestion

From the wet silo, the material is sent to the digester. The digester is usually 10 meters in length and 2 meters in diameter. It is made of steel and wrought iron. This is the main unit of the process. The digestion process can be either batch or continuous. In our country, batch processing is mostly used. As the raw materials enter the digester, steam is introduced at the bottom, and a liquor containing sodium sulfite is injected simultaneously to cover the raw materials. Sodium sulfite used is buffered with sodium carbonate or sodium hydroxide to maintain its pH of 7-9.

The digester is closed carefully. It is revolved at 2.5 R.P.M., and a temperature of 160-180 °C is maintained. The digester takes 40 minutes to attain the desired temperature, after which it gets switched off automatically, and pressure is released.

(6) Blow Tank

The cooked materials from the digester are blown into a blow tank and then pumped to a centrifugal screen for the separation of cooked from uncooked materials.

(7) Pulp Washing

The cooked materials from the tank are washed thoroughly with water using an 80-mesh sieve to remove the black liquor that would contaminate the pulp during subsequent processing steps. The pulp is washed with the required amount of water to remove soluble lignin and colored compounds. Lignin is an aromatic polymer and causes paper to become brittle. It is then thickened and finally stored in a high-density storage tower.

(8) Bleaching

The pulps obtained from chemical pulping are brown and are unsuitable for printing and writing papers, which require a bright white pulp. The color of these pulps is mainly due to residual lignin. These pulps are then sent to the bleaching unit.

In Pakistan, bleaching is done with chlorine or sodium hypochlorite and hydrogen peroxide. After washing, the unbleached pulp is sent to the chlorinator, where chlorine at 4-5 bar pressure is injected from the chlorine tank. The chlorine reacts with unbleached pulp at about 45 degrees Celsius for 45-60 minutes to give good results. The residual chlorine is neutralized with water, which acts as an antichlor.

The correct dosage is important, and a calculated amount of chlorine is needed to achieve the required brightness. After chlorination, pulp is washed with hot water at 60 degrees Celsius and is then sent to the storage tank. Pulp is dried with a hot air supply. After drying, the pulp is ready for the manufacturing of paper.

(9) Stock Preparation Plant

These are three important stages in the treatment of the pulp before its delivery to the papermaking machine. The first is the dispersion of the pulp as slurry in water, the second is the mechanical refining or beating of the fibers to develop appropriate physical and mechanical properties for the product being made, and the third is the addition of chemical additives and recycled fibers from the waste paper plant. Wet-end chemistry of paper starts from here.

(10) Paper-Making Machine

Commonly, the Fourdrinier machine is used for papermaking. Its details are given below.

(a) Flow Spreader

The flow of the spreader takes the pulp and distributes it evenly across the machine from back to front. Consistency of the stock is below 1%.

(b) Head Box

The pressurized headbox discharges a uniform jet of pulp suspension on a fabric, where special suction devices work for the removal of water.

(C) Fourdrinier Table

The endless, moving Fourdrinier fabric forms the fabric into a continuous matted web while the Fourdrinier table drains the water by suction forces.

(d) Press Section

The paper sheet is conveyed through a series of roll presses where additional water is removed and the web structure is consolidated.

(e) Dryer Section

The wet sheet of paper so formed is dried in the dryer section of the machines with the help of a rotary drum. Water is separated from the fibers either by gravity, by suction, by pressing, or by heating.

(f) Calendar Stock

The sheet is calendered through a series of roll nips to reduce thickness and smooth the surface.

(g) Reel

The dried paper is wound in the form of a reel having a final moisture content of about 6-8%.

Paper Industry in Pakistan

Paper plays such an important role in present-day economic development that its consumption is taken as an index of a country’s progress and prosperity. There was no pulp and paper industry in Pakistan at the time of independence in 1947. The country consumed about 25,000 tons of pulp and paper products per year, and all of these were imported from abroad for 25 million rupees. The start of the paper industry in our country was very slow because of various reasons, among the major ones being the non-availability of suitable fibrous raw materials.

Due to the high prices of paper in Pakistan, its per capita consumption is among the lowest in the world. Paper consumption in Pakistan is around 5 kg per person per year.

To make our country self-sufficient in this important commodity, we must utilize every source of raw materials, like non-woody and woody. Fortunately, Pakistan has enough sources of non-woody materials, which in the future can meet the requirements of our pulp and paper industry. Efforts are being made to install more pulp and paper industries in the country.

At present, there are more than 30 pulp and paper industries in the private as well as the public sectors, which are manufacturing pulp and paperboard.