Introduction:

Copper is considered to be a transition element in which the d-orbital is involved. It belongs to the 11th group and the 4th period of the periodic table. The origin of the name of this metal can be derived from aes cyprium, later corrupted to cuprum (Latin). Copper was derived from this Latin word. Most of the metals in d-block are conductors, insulators as well as semi-conductors that may or may not conduct electricity.

Basically, copper is a chemical element with the symbol Cu and it has the atomic number 29. It is considered to be a transition element that acts as a conductor because it possesses free electrons that have the ability o conduct heat or electricity. It is soft, malleable & ductile metal that shows a lustrous appearance and can be converted into sheets and wires. Copper has vast applications in building materials and can also be used in alloys with different metals. It is also used gauges and thermocouples.

Copper is considered an essential element as a trace dietary fiber. Copper is considered an essential key component in the respiratory cytochrome complex as cytochrome c-oxidase. In mollusks and crustaceans, hemocyanin is the blood respiratory pigments that are enriched in copper as a central atom. The copper is replaced by iron-containing pigment hemoglobin. The adult body comprises copper in between 1.4 and 2.1 mg per weight.

History & Discovery of Copper:

In historic times, about 10,000 years ago copper was used by humans firstly. At least five million years ago, copper was only the metal known to humans, and it possesses all the qualities that a good metal possesses. In 8700 BCE, a copper pendant was discovered in Nothern Iraq. Until 4000 BCE, gold became the second metal known to humans that possess all the qualities that a metal kept.

Then in 3000 BC, alloying of copper began with arsenic & tin. By 5000 BCE, copper was also discovered in metallurgical operations. Over the last 8000 years ago, copper is also been purified & manufactured by smelting f different ores. A different archeologist discovers copper dating to 4500 BC, which was buried in the ground in the middle ages in an ancient village in Israel.

It is also probably extracted by carbon dating that has been established at Alderly Edgein Chesire in the UK from 1890 to 2280 BCE. In the Bronze age, copper is alloyed with tin to make bronze metal. Sumerian and Egyptian artifacts of copper and bronze alloy are formed dated to 3000 BCE. In Greece, copper was known by the name Chalkos. It was an important resource for Roman, Greeks & other ancient people. Romans used it as a lump of money in the 3rd century.

The great copper mountain was a mine in Falun, Sweden that operated from the 10th century to 1992. World copper consumption is satisfied in the 17th century.

Occurrence of copper:

About 50 parts per million (ppm) of copper is present in Earth’s crust and also produced in massive stars. Naturally, copper occurs in a variety of minerals including native copper, copper sulfides, chalcopyrite, bornite, digenite, covellite, chalcocite, and copper sulfosalts & their oxide.

The largest mass of elemental copper is discovered in Michigan, US that weight is 420 tonnes. The native copper largest crystal that was discovered measured size is 4.4 * 3.2 * 32 cm. It is the 25th most abundant element in Earth’s crust. All over the world, copper is present in rich amounts which people used for conduction purposes.

Atomic Properties & Physical Properties:

Copper possesses some atomic and physical properties. Physical properties may be defined as changes in the physical state of matter. But atomic properties refer to the change in the periodic properties of the atom. Some of the important physical properties of copper are discussed below;

| PHYSICAL PROPERTIES | COPPER (Cu) |

| 1. Phase at STP | Solid |

| 2. Melting Point | 1357 K, 1084 °C, 1984 |

| 3. Boiling Point | 2835 K, 2562 °C, 4643 |

| 4. Density | 8.96 g/cm3 |

| 5. Heat of fusion | 13.26 KJ/mol |

| 6. Heat of Vaporization | 300.4 KJ/mol |

| 7. Molar heat of capacity | 24.40 KJ/mol |

| 8. Oxidation State | -2, 0, +1, +2, +3, +4 |

| 9. Electronegativity | 1.90 (Pauling Scale) |

| 10. Ionization Energy | 745.5 KJ/mol |

| 11. Atomic Radius | 128 pm |

| 12. Van der Waals Radius | 140 pm |

| 13. Crystal Structure | Face centered cubic |

| 14. Magnetic Ordering | diamagnetic |

| 15. Thermal conductivity | 401 W/(m-K) |

Electronic Configuration of copper:

The electronic configuration is the distribution of electrons in the shells and subshells according to their energy levels. The electronic configuration of copper is:

Cu = [Ar] 4d10, 3s1

This electronic configuration has an exception that all electrons should fill according to their energy level. So, electrons remain stable when they first fill in the lower energy orbits. The subshell or shell close to the nucleus has lower energy. So in lower orbit, there is less acceleration due to low energy and the electron feels stable. Also to attain symmetry electrons should fill first in the d orbital and then in the s-orbital due to attain stability and to attain symmetry. For stability, it is also noticeable that a fully filled orbital is more stable than that of a half-filled orbital or partially filled.

If we talk about the trends of copper in groups and periods then:

- The Atomic Size of copper is small because of a strong force of attraction between the nucleus and outermost shell.

- Ionization energy value increases. Because of its small size, it is difficult to withdraw an electron from the outermost shell due to the strong force of attraction between the nucleus and electrons.

- Electron affinity increases. An increase in ionization energy causes an increase in the value of electron affinity because due to the strong force of attraction and small atomic size it is difficult to insert an electron in the outermost shell.

- Electronegativity increases. By the above two reasons, it is concluded that its ability to attract shared pair of electrons increases.

- Also shielding effect increases but the effective nuclear charge decreases.

Chemical Reactivity & Reactions:

Copper does not react with water. All metals in the periodic table are listed according to their chemical reactivity. For example Sodium, it is too reactive, so it explodes in water. Some like gold, silver, etc appear to be unchanged because they all are less reactive or unreactive. Copper is low in reactivity that’s why low reactivity is linked with malleability which makes it ideal for conduction. Due to their less reactiveness, these are used in architecture, to save corroded statues, and also in the patination (It is the covering of patina on the surface of the metal, statues, etc) process. It reacts slowly with the atmospheric oxygen to form a brown-black copper oxide layer which prevents rusting and corrosion.

Chemistry of Patination:

Patination is basically the coating of patina on antique pieces. The patina is basically a substance or varnish that is a mixture of copper chlorides, sulfides, sulfates, and carbonates that depend upon environmental conditions. Patina may be of many colors:

- Cupric Nitrate Patina (Blue-Green)

- Ammonium Sulfide Patina (Blue-Black)

- Liver of Sulfur Patina (Brown- Black)

In the patination it is very much important to make patina so, patina is formed and manufactured by following reactions:

- Copper is oxidized to cuprous oxide which is of red or pink color. By the oxidation of copper, the cuprous oxide formed is actually Copper (I) oxide.

4Cu + O2 → 2Cu2O

- The copper (I) oxide is reacted again with oxygen & oxidized to form Copper (II) oxides that is black in color.

2Cu2O + O2 → 4CuO

- If by burning fossils Sulfur is obtained. This obtained sulfur reacted with sulfur to form copper (II) Sulphides:

Cu + S → CuS

- Over the years, CuS and CuO react with Water (H2O) & Carbon dioxide (CO2) to form Cu2CO3(OH)2, Cu3(CO3)2(OH)2 & Cu2SO4(OH)6. These all products formed include patina in it that is used to coat a layer called patination. Basically, patination is done by distressing. Patina is applied directly to that material which we want to protect from rust and corrosion.

Compounds of Copper:

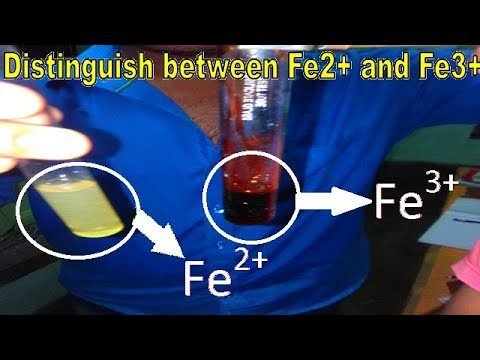

Copper may form bonds with oxides, chlorides, and sulfides. Two elements copper & oxygen may form copper oxides. A very unique reaction between copper and oxygen may form Oxides of copper. It may form copper (I) oxides, Copper (II) oxides, copper sulfates, and many other compounds of copper. Now, we will discuss the different compounds of copper:

Copper (I) oxide:

It is also called cuprous oxide with the formula Cu2O. It is a red-colored solid whose appearance of color may depend upon the size of particles present in it. It is prepared by several methods:

- It is formed when four moles of copper and one mole of oxygen react with eachother they form Cu2O (Copper (I) oxide).

4Cu + O2 → 2Cu2O

- Copper (I) oxide is also manufactured on the base of Fehling’s and benedict’s tests. Both tests are used to distinguish the reducing sugar either aldehydes or ketones.

- Fehling’s Test occurs when reducing sugar either glucose or fructose may react with 2 moles of copper and 5 moles of OH- ion it giving Brick red precipitates of Cu2O along with three moles of water.

C6H12O6 + 2Cu + 5OH → C6H11O7 + Cu2O + 3H2O

- Benedict’s Test can manufacture and form Cu2O when an aldehyde gets reacted with the Cu it gives a carboxylic acid along with brick red precipitates of Cu2O.

CH2OH + Cu2+ → CH3COOH + Cu2O (Brick red ppts.)

Copper (I) oxides possess the following properties:

- They are solids and show diamagnetic behavior because it has paired electrons in their bonding molecular orbitals.

- In the coordination sphere, these oxides show tetrahedral geometry having a bond angle of 109.5 degrees.

- Due to tetrahedral geometry, it is a polymorph of SiO2.

- These dissolve in concentrated ammonia solution to form a colorless complex [Cu(NH3)2]+.

- It dissolves in HCl solution to give CuCl2-.

- Cu2O is the most studied material which is used as semi-conductor diodes.

Copper (II) Oxides:

Copper (II) Oxide is an inorganic compound with the formula CuO. It is a black solid which is the product of copper mining. It is produced by pyro-metallurgy which is one of the most important stages in copper extraction and isolation. Copper (II) oxides are prepared by:

- The ores in the impure form are reacted with an aqueous mixture of ammonium carbamate, ammonia, and oxygen to give copper (I) amines. These amines are decomposed with steam to give CuO.

- It is also formed by heating copper in the air at 300°C – 800°C.

2Cu + O2 → 2CuO

- It is also prepared by heating copper to nitrate, copper to hydroxide & basic copper to carbonates:

2Cu(NO3)2 → 2CuO + 4NO2 + O2

Copper (II) oxides are also reacted with the mineral acids. Chemical reactions of copper (II) oxides are as follows:

CuO + 2HNO3 → Cu(NO3)2 + H2O

CuO + 2HCl → CuCl2 + H2O

CuO + H2SO4 → CuSO4 + H2O

All the compounds of copper may possess some of the following uses. So, for this purpose CuO can possess some of the following uses:

- Used in pyrotechnics & fireworks.

- USed in Edison-Lalande cell & lithium battery.

- Used as a pigment in ceramics.

Copper Peroxide:

It is an inorganic compound with the formula CuO2. It has a dark olive green appearance. It is an oxide of copper (II) with the two oxygen atoms as peroxide units. It is prepared by reaction of a cold solution of hydrogen peroxide and Schweizer’s reagent.

- Schweizer’s reagent is basically the metal amine complex with the formula [Cu(NH3)4(H2O)2](OH)2. It is a deep-blue compound that is used to purify cellulose.

- It is also prepared with the copper hydroxide and dilute ammonia solution.

- It may also form by a very slow reaction of cupric oxide with cold hydrogen peroxide.

It possesses some of the properties:

- When wet copper peroxide decomposes, at a temperature of 6 degrees it is far more stable than dry.

- Its molar weight is 95.94 g/mol.

- It is decomposed into other oxygen and other copper oxides.

Copper (II) Chloride:

It is also called cupric chloride. In anhydrous form, it is yellowish-green in color but when it absorbs moisture it forms blue-green dihydrate. CuCl2 in anhydrous form may adopt the structure of cadmium iodide.

An aqueous solution which is manufactured by the Copper (II) chlorides contains a wide variety of different complexes that depends upon temperature, pressure and the presence of additional chloride ion.

Copper (II) chloride can carry out many of the reactions. Just like hydrolysis, redox reaction, and coordination complexes.:

- The first reaction they give is hydrolysis. In hydrolysis, copper chloride is reacted with the strong base NaOH to form copper hydroxide precipitates and NaCl salt.

CuCl2 + 2NaOH → Cu(OH)2 + 2NaCl

- Copper chloride also gives a redox reaction. In the first reaction, at 1000 degrees of temperature it is decomposed to Cucl and Cl2 gas.

2CuCl2 → 2CuCl + Cl2

- It also reacts with several metals to form CuCl. CuCl2 is reduced by SO2 in CuCl and HCl and sulphuric acid.

2 CuCl2 + SO2 + 2 H2O → 2 CuCl + 2 HCl + H2SO4

- CuCl2 reacts with HCl or other chloride sources to form complex ions. It also forms a dimer of red, green, and yellow complex ions.

CuCl2 + Cl– ⇌ CuCl3–

CuCl2 + 2Cl ⇌ CuCl42-

- CuCl2 also forms coordination complexes with the ligands such as ammonia, pyridine, and triphenylphosphine oxide.

CuCl2 + 2 C5H5N → [CuCl2(C5H5N)2] (tetragonal)

CuCl2 + 2 (C6H5)3PO → [CuCl2((C6H5)3PO)2] (tetrahedral)

It possesses the following uses. It has many applications in daily life.

- It acts as a co-catalyst in Wacker’s process. In this process, ethene is converted into ethanol. In this process PdCl2 is reduced to Pd and CuCl2 is again re-oxidized to PdCl2. These all steps are involved in the Wreckers process.

C2H4 + PdCl2 + H2O → CH3CHO + Pd + 2 HCl

Pd + 2 CuCl2 → 2 CuCl + PdCl2

4 CuCl + 4 HCl + O2 → 4 CuCl2 + 2 H2O

- It also acts as a catalyst in the production of chlorine. The Deacon’s Process is involved in the manufacturing of Chlorine.

4 HCl + O2 → 2 Cl2 + 2 H2O

- It is also used in the manufacturing & synthesis of different organic compounds.

Copper Sulphate:

It is an inorganic compound having the chemical formula CuSO4. It is bright blue in color. It is produced in the industry when copper metal is treated with hot concentrated sulphuric acid. It is also prepared by slow-leaching low-grade copper ore into the air.

Commercially copper sulfate is usually 98%. Pure anhydrous copper sulfate contains 39% copper and 61% sulfate by mass.

It is also be prepared by the following methods:

- By heating copper scrap removed from ores with sulfur to form copper sulfide which is then oxidized to copper sulfate.

- By heating, copper sulfide ores produce copper oxide which is treated with sulphuric acid to form copper sulfate.

Commercially, copper sulfate is present in the crystal form. The four commonest grades based on diameter sizes are:

- Large crystal (from 10mm to 40mm)

- Small crystal (from 2mm to 10mm)

- Granulated and snow crystals (less than 2mm)

- Windswept powder (less than 0.15mm)

Copper sulfate also possesses some the uses:

- It is used as a fungicide and herbicide.

- It acts as an analytical reagent.

- It is involved in rayon production.

- It is used in the drying etching process.

Isotopes Of Copper:

Isotopes are elements or groups of elements that have the same atomic number but different mass numbers. So, copper has two stable isotopes. 63Cu & 65Cu. It has 27 radioisotopes. The most abundant isotope is 63Cu which has 69% naturally occurring copper. It has a relative abundance of 68.94 % and 65Cu has a 31.06% relative abundance.

63Cu has 29 protons & 34 neutrons in the nucleus but 65Cu can possess 29 protons & 36 neutrons. 64Cu and 67Cu are unstable isotopes of copper whose half-life (t1/2) is 12.70 hours and 61.83 hours. The least stable isotopes of copper are 54Cu which have a half-life of approximately 75ns.

Isotopes of copper possess the following medical applications:

- 63Cu, 62Cu, 61Cu, and 60Cu are used for diagnostic purposes.

- 67Cu and 64Cu are used for targeted therapy.

- 64Cu is also used for PET imaging biological molecules.

| ISOTOPES | HALF-LIFE (t1/2) | NUCLEAR SPIN | NUCLEAR MAGNETIC MOMENT |

| 59Cu | 1.36m | 3/2 | – |

| 60Cu | 13.7m | 2 | 1.219 |

| 61Cu | 3.35h | 3/2 | 2.14 |

| 62Cu | 9.74m | 1 | -0.380 |

| 64Cu | 12.701h | 1 | -0.217 |

| 66Cu | 5.09m | 1 | -0.282 |

| 67Cu | 2.580d | 3/2 | – |

| 68Cu | 31s | 1 | – |

| 69Cu | 2.8m | 3/2 | – |

Extraction & Purification of copper:

Extraction means taking out original copper from the ores and purification means purifying it with impurities. The method of copper extraction depends upon the nature of the ore. Extraction and purification possess some of the following stages:

Mining of Copper:

About 200 years ago, the UK was the world’s largest source of copper mining but is now the largest source of mining in Indonesia and Chile. They produce tonnes of copper per year. Basically, the main ores of copper are sulfides and oxides. When the copper is mined in ore form it contains gangue and other metals with the following percentages:

- Bornite = It contains 63% of copper.

- Malachite = contains 58% of copper.

- Azurite = contains 55% of copper.

- Chalcopyrite = It contains 35% of copper.

Copper element is found throughout the earth’s crust. They also occur in sedimentary and igneous rocks. About 10 km of earth’s crust every rock tonne contains 33g of copper. Copper can be extracted from ores by the following methods which are discussed in the complete article of Nickel. Copper can also be extracted in the following ways:

- Underground: In this vertical shaft of ore is dipped in the Earth & driving horizontal tunnels in the Earth.

- One Pit: About 90% of ores are extracted by this process. In this process, Ores are quarried after the removal of the surface layer. The ore obtained is reacted with the Sulphuric acid. The ore dissolves copper to form copper sulfate. Then the copper is recovered from electrolytic refining.

- Froth floatation process.

- Gravity separation.

- Magnetic separation.

Stage 1: Crushing and grinding:

The ore obtained is then crushed and ground. It is the first step in which the impure ore is ground and crushed in the crusher. Which makes it ready to separate impure substances in the Froth floatation process.

Stage 2: Froth Floatation process

In this process, the ore in the powdered form gets mixed with paraffin oil to make the copper particles repellant to water. It is then transferred to the wash bath that contains the foaming agent which produces many bubbles in it. When the flow of air is passed through them copper ions move upward to the surface of the water along with bubbles.

And the sedimentary material remains at the bottom as gangue. The upper gone copper is then skimmed out of the container. This skimmed-out copper is then roasted to make it dry and the mixture of water and paraffin il is recycled again.

This process will give 25% of copper by mass. Therefore, it is necessary to do the froth floatation process. The skimmed copper is also transported throughout the world.

Step 3: Roasting

This is the most important stage in which copper mineral is converted into copper metal. In this stage, chalcopyrite is taken as raw material, which means iron and sulfur are removed in its process. In this process, two basic methods occur:

- Chalcopyrite CuFeS2 is changed to copper oxide.

- Some of the sulfur is removed as sulfur dioxide.

2CuFeS2(s) + 3O2(g) → 2FeO(s) + 2CuS(s) + 2SO2(g)

This reaction occurs when concentrated ore from the froth floatation process is heated at 500°C – 700°C temperature. The product obtained from roasting is called calcine. As SO2 is hazardous, it is necessary to remove it.

Step 4: Smelting:

Now, in this process, more heating is carried out. The calcine obtained is heated at 1200°C with silica and limestone. When it reacts with silica it melts and forms an unnecessary mass called Iron silicate slag FeO. SiO2 floats on the surface of the liquid. The floating material is further collected.

After the heating when it melts, it gets mixed with the liquid. So, iron silicate slag floats on water, and copper remains in the water. This leftover mixture of water and copper is called matte.

FeO(s) + SiO2(s)→ FeO.SiO2 (iron silicate slag)

Step 5: Conversion of matte to blister copper:

The liquid mixture produced as matte is further oxidized with air to form blister copper. Matte from the smelters is poured into anode casting molds. The following reactions take place:

- When iron oxide is oxidized, the iron sulfide releases to form iron silicate slag.

2FeS(l) + 3O2 + SiO2(l) → 2FeO.SiO2 + 2SO2 (g)

- By reduction of copper sulfide formation occurs.

Cu2S(l) + O2(g) → 2Cu(l) + SO2

Step 6: Anode casting:

Anode casting is one of the most important procedures in which pure 99% copper is obtained. The word “blister” means the formation of sulfur dioxide bubbles along with copper. It means copper remains downward and sulfur dioxide comes with the bubbles upward.

The anode casting is basically a turntable that consists of small molds. Therefore, the molten copper is poured into this huge wheel and it moves very slowly in a circular orbit for the next mold. Moreover, after some time copper cools and solidifies to the anode. The molds contain small supporting arms which are used to lift solidify copper.

Step 7: Electrolytic Refining:

The blister copper contains mostly 99% of copper but in today’s market, its purification is not enough. So, it is again pure by using electrolytic refining. This refining is carried out in the electrolytic cell. This type of refining produces high-quality and purity of copper.

In the electrolytic cell, there must be two electrodes anode and a cathode. The blister copper in the form of sheets or solidify copper acts as an anode having a positive charge on it and any other metal acts as a cathode having a negative charge. In this electrolyte used is an aqueous mixture of 3-4% copper sulfate & 11-16% sulphuric acid.

The apparatus consists of electrodes in which anodes are hung between cathodes. In this process, 0.2 -0.4 volts of potential difference is applied which is necessary for this process. When current passes through electrodes, the copper ions from the anode release and enter the electrolyte in the form of Cu2+.

Then, the cathode releases two electrons and copper ions take two electrons to form copper atom Cu. The reaction at anode and cathode are as follow:

AT CATHODE: Cu2+(aq) + 2e− → Cu(s)

AT ANODE: Cu(s) → Cu2+(aq) + 2e−

Uses Of Copper:

Copper possesses some of the uses:

- It is the traditional metal used to make coins along with silver & gold.

- All gun metals contain copper in it.

- Most of the copper is used in electrical equipment such as wires and motors bcz it is good conductor of electricity.

- It is used in construction sites and in heat exchangers to equalize the temperature of equipment.

- Copper Sulphate is used in agricultural sites to kill fungus, pests, and many other herbs.

- The copper compound is used in a chemical test for sugar detection.

- It regulates enzymes to transfer energy.

- Genetic diseases can affect both abilities to use copper properly.

- Copper complexes are found in the hemolymph of mollusks and crustaceans.

Display Diagram of Cu Extraction & Purification: